CORRUGATED BOXES

We know now that boxes are made of corrugated paperboard, or simply “board” for short. There are several kinds of corrugated board, all made by combining paper, heat, adhesives, and pressure.

It starts off as rolls of liner or paperboard, similar in appearance to the brown paper in grocery bags. These rolls can weigh more than two tone each, and hold paper that cold stretch several miles.

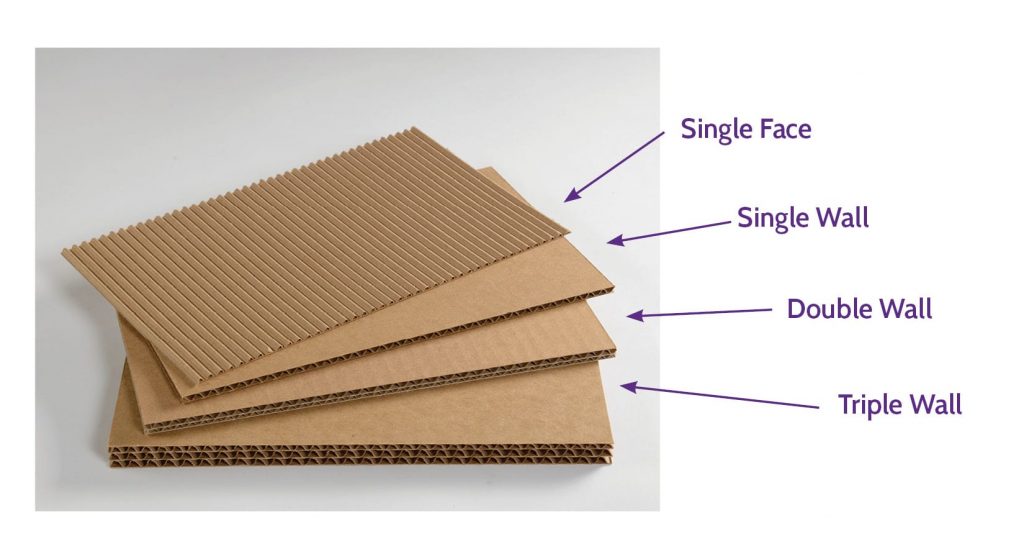

Corrugated board can be made up of one, two, or even three layers of flutes and liners, depending on how strong the box needs to be.

There’s a box for practically every purpose, and building it begins when the box-plant salesperson asks the box-buying customer just what kind of box is needed, how many, and how soon?

Then a box designer starts planning. He or she has plenty to consider: the size and shape of the customer’s product, the size and shape the the finished box, the strength of the material it’s made of, the color of the corrugated board, the size of the flutes or paper ridges within it, the number of boxes to be made, the coatings and printing they’ll bear, and just when they’ll need to be made and shipped. How will the customer put the box together, fill it, and close it? How will the customer’s customer open the box? Will the product- filled box be moved by hand or by fork lift? Stacked in tall piles or singly? How roughly will it be treated?

Boxes are made at special factories called Box Plants. Corrugated boxes are designed to be very strong. They are made of corrugated paperboard, which is different from the stiff paper known as “cardboard.” Look at the edge of corrugated paperboard, and you will see a row of air columns. the air acts as a cushion, while the paper columns make the material strong. Each box is made to hold something just right, protect it from banging around, and keep it from spilling. Boxes are made with important information printed on them about what’s inside, or how to lift or move them. Carefully designed inserts hold items in place so they won’t spill or become damage.

Corrugated boxes are everywhere, caring products from all over the world and just down the hall. The pizza you eat probably comes in a brightly colored corrugated box. Your son or daughter, sister and brothers might even use a big corrugated washer, dryer or dishwasher box for a playhouse. You might flatten and collect corrugated boxes for recycling.

B Flute

C Flutre

E Flute

Double Wall

Triple Wall

Supplier of Custom Corrugated Boxes and Displays

Please call (714) 671-4182 or send a message for a quick, custom quote!

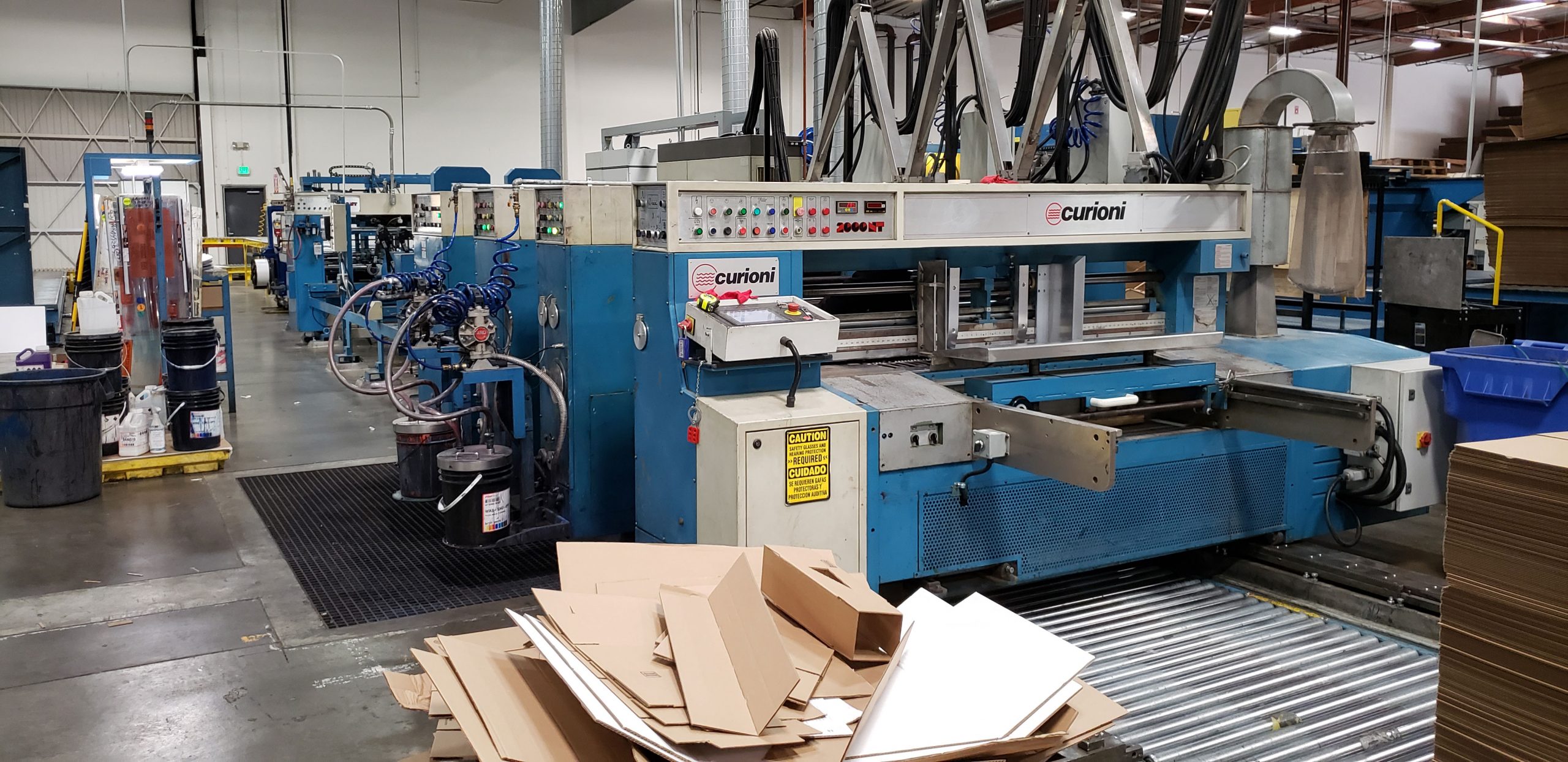

Custom folder gluer capable of gluing special box designs including crash lock bottoms and automatic lock bottoms.

Corrugated fiberboard or “combined board” has two main components: the liner and the medium. Both are made of a special kind of heavy paper called containerboard. Linerboard is the flat material, typically on the outer surfaces of the board but also on the inside for some structures, that adheres to the medium. Medium is the paper that is formed into arches or flutes on the single facer and glued between the linerboard facings.

Flutes

Architects have known for thousands of years that an arch with the proper curve is the strongest way to span a given space. The inventors of corrugated fiberboard applied this same principle to paper when they put arches in the corrugated medium. These arches are known as flutes and, when anchored to the linerboard with an adhesive, they resist bending and pressure from all directions.

Innovation And Research

When a piece of combined board is placed on its end, the arches form rigid columns, capable of supporting a great deal of weight. The flutes act to keep the linerboard sheets separated, maximizing the bending rigidity of the board. When pressure is applied to the side of the board, the space in between the flutes acts as a cushion to protect the container’s contents. The flutes also serve as an insulator, providing some product protection from sudden temperature changes. At the same time, the vertical linerboard provides additional strength and protects the flutes from damage.

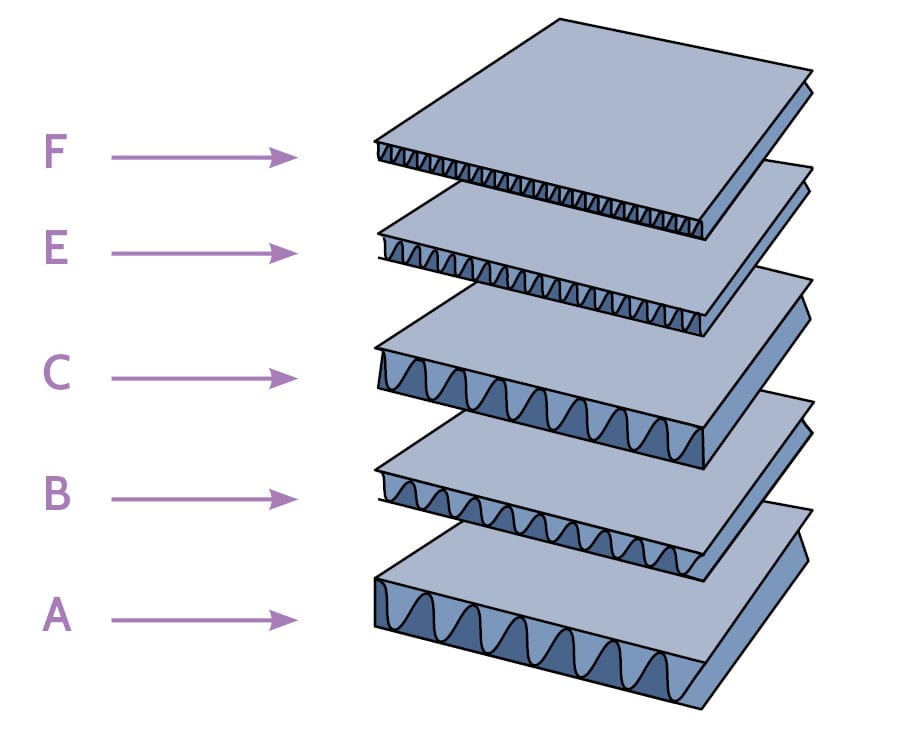

Flutes come in several basic designations. Flutes with the same designation have similar size, but may have various flute profiles and number of flutes per foot within a given designation:

- A flute was the original flute profile for corrugated board. It has about 33 flutes per foot.

- B flute was then developed for canned goods that were self-supporting, and so did not require boxes that supported much load. It has about 47 flutes per foot.

- C flute was next developed as an all-purpose flute, and it has about 38 flutes per foot.

- E flute was the next successful flute profile, and it has about 90 flutes per foot.

- F flute was developed for small folding carton type boxes. It has about 125 flutes per foot.

Single Face

Single Wall

Double Wall

Triple Wall

Generally, larger flute profiles deliver greater cushioning and vertical compression strength, while smaller flute profiles provide enhanced graphics capabilities. Smaller flutes such as E and F also provide enhanced structural capabilities for primary (retail) packaging compared to paperboard (folding cartons). There is a good deal of variance across the industry in the range of flute sizes based upon the container characteristics that are desired for each application, as well.

Supplier of Custom Corrugated Boxes and Displays

Please call (714) 671-4182 or send a message for a quick, custom quote!