Different Board Grades

If you are using high volumes of packaging, chances are you will be familiar with corrugated cardboard. If you are not familiar with Corrugated and Cardboard Board Grades, the information below will help you select the correct board grade that you are looking for. This guide aims to explain and clarify everything you could need to know about corrugated & cardboard. We can help you pick from different board thickness to white or Kraft Paper.

Composition of Material

Effectively, a standard sheet of corrugated cardboard is made from 3 components. These are a sheet of corrugated or “fluted” material in the centre, placed between 2 layers of paper – the outer and inner liners.

Each side of the fluted material is glued to the flat paper liner during manufacture. The glue fixes the flutes in position and adds rigidity and stability to the papers.

You can see a basic diagram highlighting the fluting and liners below.

Types of Paper

One of the key factors that define the properties of the corrugated material is the types of paper used. Despite cardboards’ widespread use, there are 2 main types of paper that are generally used for the liners. These are known as Kraft and Test liners. Kraft paper is manufactured from softwood trees. Due to the “virgin” fibres, it is both the strongest type of paper and also the easiest to print on. As a result, it is the most commonly used outside liner when selecting material to produce corrugated boxes and packaging.

Test paper is actually a double layered (or duplex) paper. Being recycled, Test paper is not as strong as Kraft, or easy to print on, so is commonly used for the inside liner. It is, however, less costly than Kraft paper.

Each liner type is actually comprised of two distinct layers. A basic layer is used adhesion and strength, whilst a finer “cover” layer is used mainly for improved aesthetics and to aid printing. However, despite Kraft and Test liners being so popular, there are in fact a number of other options. The available paper grades for outer and inner liners when manufacturing cardboard are as follows:

- KRAFT (K): Virgin Kraft paper

- TEST 2 (T2): Partly recycled liner paper

- TEST 3 (T): Fully recycled liner

- CHIP (C): Waste based liners

- FULLY BLEACHED WHITE (BW): Fully bleached Kraft liner

- WHITE TOP (WT): White coated recycled liner

- MOTTLED KRAFT (MK): Mottled white Kraft

- OYSTER (OY): Mottled test liner

- SEMI CHEM (SC): Virgin fibres using neutral sulphite semi-chemical process

- WASTE BASED (WB) 100% recycled fibres

The final 2 paper types listed here are those most commonly used for flutes, and less often used for liners.

Wall Types

However, an additional fluting section – and additional liner, can be added to make what is known as “double wall” or “double walled” material.

This effectively adds extra rigidity and strength, making it suitable for packaging heavier items and adding additional protection for items that may more delicate or expensive.

You can see an example below.

![]()

Single wall corrugated cardboard

Besides the varying paper weights and types, the type (and number) of fluting must also be considered.

At a basic level, a corrugated board is made up of the two liners, plus the single fluting. This is known as a “single wall” board. You can see a diagram indicating this below.

![]()

Double wall corrugated cardboard

Finally, if the items you are shipping are particularly heavy or large (for example automotive parts, industrial equipment etc.) then a “triple walled” grade can also be used. As the name suggests, this adds another section of fluting and additional liner.

Also referred to as Tri-Wall (which is the brand name of the manufacturers too), you can see a basic diagram of this below.

Triple wall corrugated cardboard

Flutes

The final aspect of the corrugated board that can affect its performance (and weight and cost), is the flute type.

The flute is the “corrugated” section between the two liners, and by changing its’ height (and therefore the size of the flutes) it is possible to achieve different performance characteristics.

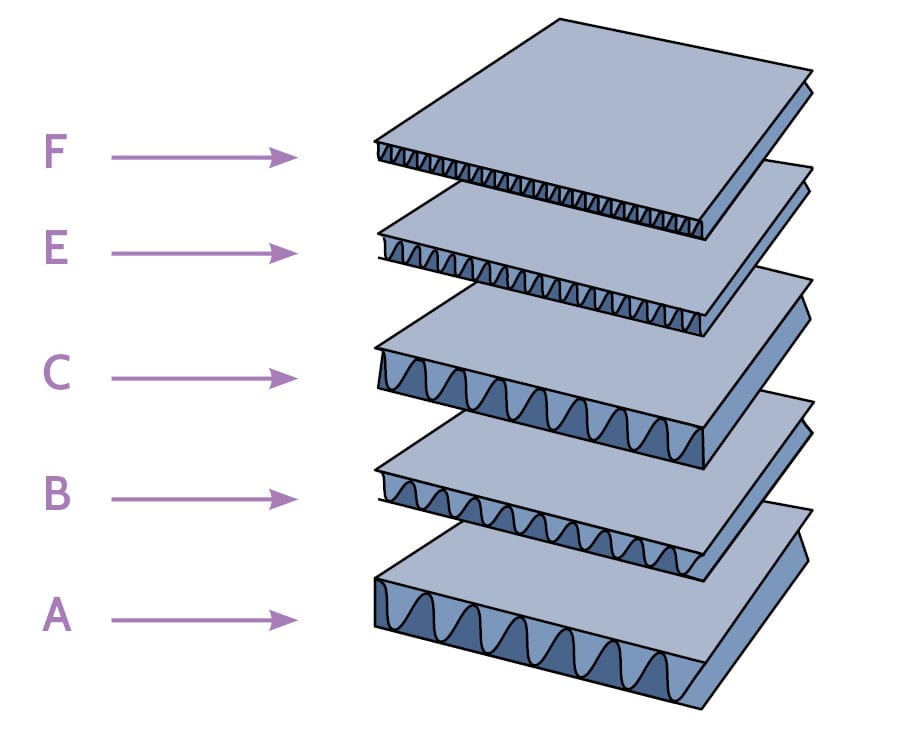

This can vary from very fine flutes such as “E” to manufacture lightweight retail cartons (being very good to print onto), through to a more coarse flute such as an “A” or “B” flute more usually used for transit packaging.

As in the examples above, with double walled material, it is possible to combine one or more flutes to create a grade such as an “EB” or “BC” flute. This can offer a rigid structure perfect for heavier items, whilst also allowing an improved aesthetic outer appearance and printing surface.

![]()

BC Flute corrugated cardboard

The flute itself is usually manufactured from a waste based fluting (WBF – i.e., fully recycled material) or what is known as semi-chem fluting (SC).

Typical paper weights used for fluting are as follows:

A FLUTE: 1/4″

B FLUTE: 1/8″

C FLUTE: 3/16″

E FLUTE: 1/16″

BC FLUTE: Double Wall – 5/16″ -Combination of B + C flutes

C FLUTE is the most common SINGLE WALL board grade Used.

CB FLUTE is the most common DOUBLE WALL board grade Used.

Simply knowing how a corrugated board grade is manufactured, and its’ component parts, doesn’t necessarily allow you to make an informed choice on the type of material you should be using for your packaging.

As such, the below information provides a little more detail on each of the most commonly used flute types.

E Flute

E flute is approximately 1mm to 1.5mm in thickness, providing a very fine flute. This not only gives it excellent compression strength and crush resistance, but also means it provides a high quality surface for printing.

As a result, it is commonly used smaller cartons, where good quality print is required, plus die cutting applications.

E-Flute has a thickness of 1/16th

![]()

B Flute

B flute is amongst the most commonly used types of cardboard used for packaging applications. Being 3mm in thickness, it is exceptionally versatile and can be used in both die cutting and regular case-making processes

It gives good all-round performance in all types of packaging.

It typically has a thickness of 1/8th”.

![]()

C Flute

Between 3.5mm and 4mm in thickness, C flute offers greater compression strength than B Flute. This means it provides better stacking strength when used for lightweight products.

However, it can, if used in the wrong application, be prone to crushing.

C-flute has a thickness of 3/16ths”.

![]()

BC Flute

Being 6mm to 7mm in thickness, this double wall material combines both B and C flutes together. This gives a good all round performance, making it common for producing shipping boxes that offer a higher level of transit protection. BC Flute has a thickness of 5/16ths”

Due to this, only basic print (such as flexographic) tends to be added.

![]()

Choose your Product Weight & Box Size Below.

| Minimum Bursting Test, Single Wall, Double Wall (lbs per sq inch) | Minimum Edge Crush Test “ECT”(lbs per in width) | Minimum Combined Weight of Facings (incl. Centers of Double Wall) | Maximum Weight of Box and Contents (lbs) | Maximum Outside Dimensions (L+W+D inches) |

| Single Wall | ||||

| 150 | 26 | 66 | 20 lbs | 50 inches |

| 175 | 29 | 75 | 30 lbs | 60 inches |

| 200 | 32 | 84 | 65 lbs | 75 inches |

| 250 | 40 | 111 | 80 lbs | 85 inches |

| 275 | 44 | 138 | 95 lbs | 95 inches |

| 350 | 55 | 180 | 120 lbs | 105 inches |

| Double Wall | ||||

| 200 | 42 | 92 | 80 lbs | 85 inches |

| 275 | 48 | 110 | 100 lbs | 95 inches |

| 350 | 51 | 126 | 120 lbs | 105 inches |

| 400 | 61 | 180 | 140 lbs | 110 inches |

| 500 | 71 | 222 | 160 lbs | 115 inches |

| 600 | 82 | 270 | 180 lbs | 120 inches |